Smart Technologies

AI for diverse Production Processes

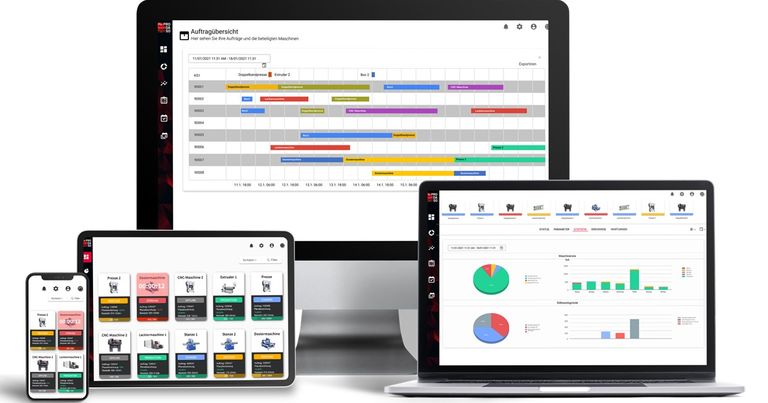

Core Functionality of the cloud-based software solution DeepPro:

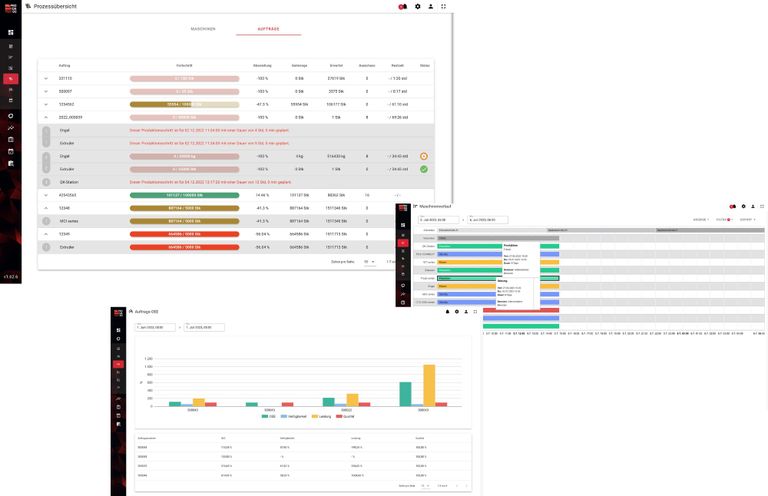

- Real time monitoring: complete and transparent overview of production

- Extensive Machine and System Compatibility

- AI-Based planning & control Production management based on Real-Time Data

- AI-Based process mining: in-depth process analysis for identifying previously unseen patterns of disruptions and inefficiencies

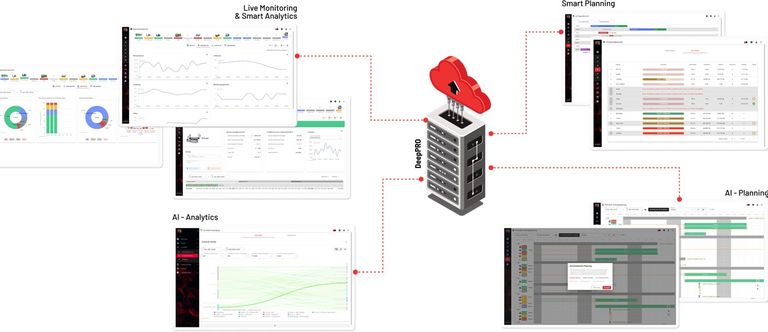

Complete integration of all production-related data in the cloud

By comprehensively connecting and integrating all system, you achieve enhanced transparency along the production line. Precise root cause identification is enabled by linking data from machines, products, orders, and resources.

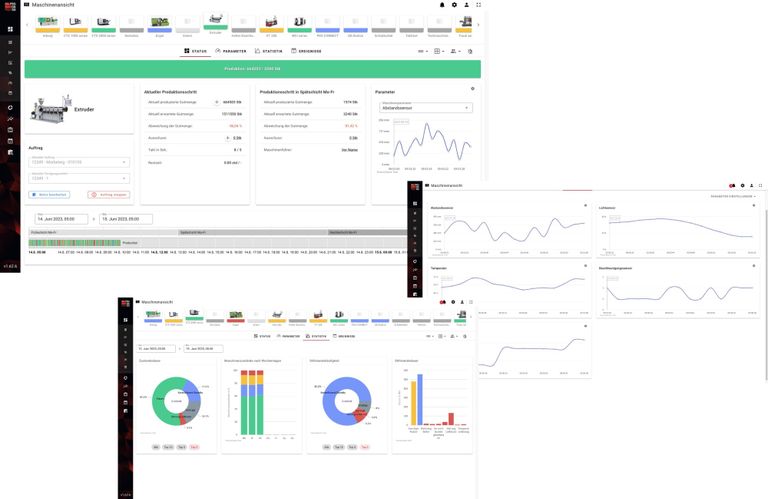

Live Monitoring

Comprehensive connectivity and real-time overview of the entire machinery and all production processes

- Individual dashboards with reports and statistics enable comprehensive analysis of current and past production processes

- Full transparency in manufacturing across all machines

- Insight into real-time and historical machine conditions

- Analysis of Production, downtime, and setup processes based on variety of key performance indicators (KPIs)

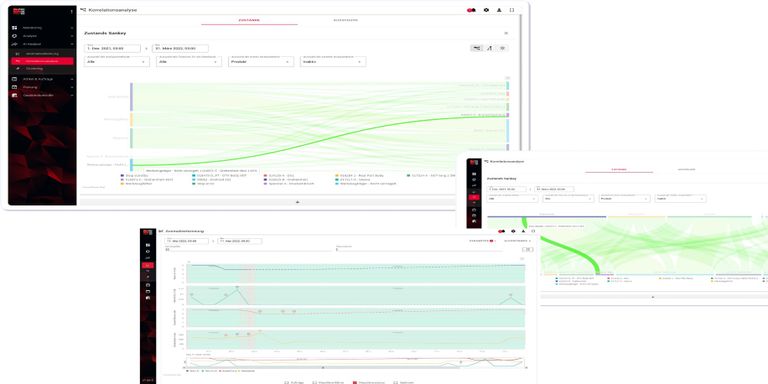

AI-Analytics

Automatic and in-depth AI-Analysis of process and machine data using machine learning methods:

- AI can identify unrecognized optimization potentials that can effectively reduce costs, promote sustainable practices, and enhance resources efficiency.

- Trend analysis and forecasts of future process details are possible.

- Intelligent pattern recognition enables anomaly detection, process risk analysis, and correlation analysis to be performed.

- Predictive maintenance is enabled through the use of artificial intelligence.

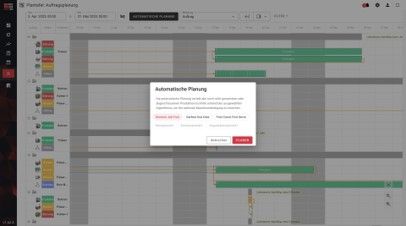

Smart Planning

Intuitive rough and fine planning of available capacities using real-time information from the shop floor

- Immediate and detailed information enables rapid response and re-planning in case of deviations and changes.

- Scrap is reduced, delivery reliability is increased, and efficiency is enhanced.

- Multivariable planning based on the current order situation.

- Consideration of past and current machine utilization

AI Planning

Self-Optimizing Production Planning and Control through Artificial Intelligence

- Real-time driven production planning using AI methods.

- Event-driven simulation methods for determining the optimal distribution of capacities.

- Replication of the production through a digital twin.

- Achievement of goals through a customized production process based on individual objective functions.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details and accept the service to view the translations.